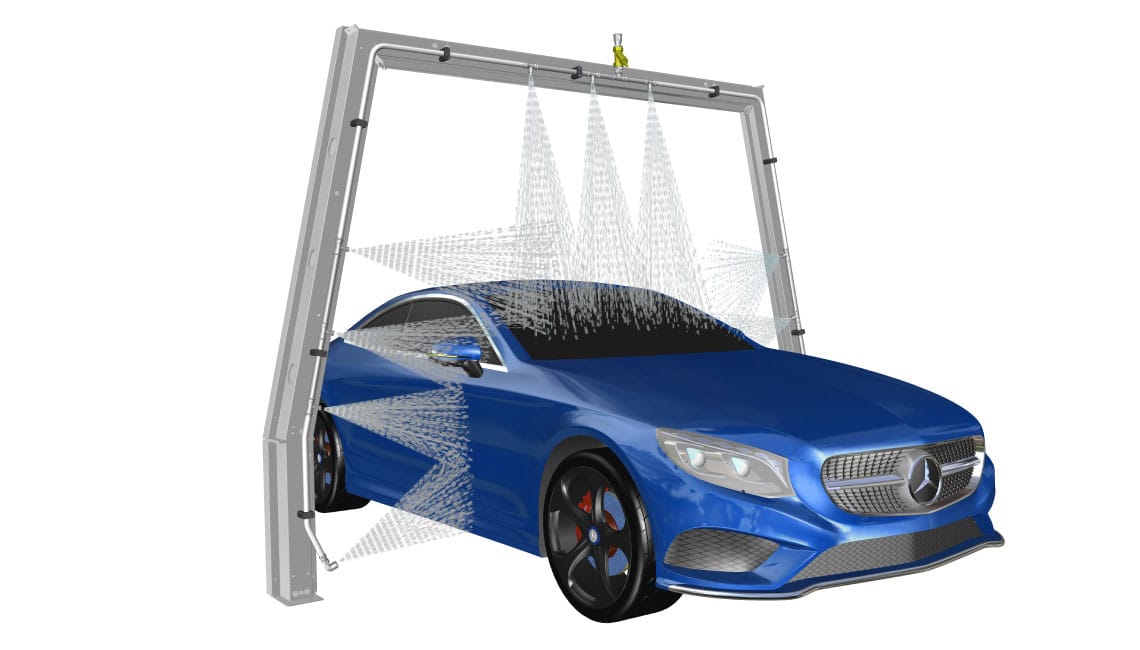

AUTOMATIC PRE-WASH ZONE

Foam spray device, aluminum premium arch, LED illumination, including program indication

Eye-catching entrance portal made from powder-coated aluminum with vehicle and height identification system. Front side covered with translucent, labeled plastic plates. Illuminated system: 1 Lamp compartment in lateral beam, 1 lamp compartment in left and right side beam, up to 6 additional illuminated LED-program indications in left side beam.

A program ticker can be purchased optionally.

Alternative arch versions:

a) Without program indication (left side piece also with drive-in pointers)

b) Without foam fan spray jets and foam reactor /as pre-spray arch with flat spray jets)

Foam flat spray jets from Christ

For special visual optics on the foam arch. The foam carpet is applied evenly and well targeted. Cost-efficient: Reduced chemical and water consumption.

Program ticker

For displaying advertising and promotions. With PC software for free text programming.

Pre-spray device, aluminum premium arch, not illuminated

Frontside covered with labelled plastic plate coverings. No lighting system. Alternative arch model: With foam flat spray jets and foam reactor (instead of flat spray jets)

Rim spray device free-standing.

Rim cleaner is sprayed onto the rims in order to losen the dirt. The device is light barrier controlled.

Chemcial spray device front/rear.

This special device is irreplaceable in express wash tunnel concepts. The spray device consists of two spray pipes and is delivered with 2 dosing pumps (for various pre-cleaning chemicals). The first spray pipe sprays against the lower front area (insect area) and the second spray pipe against the lower rear area (around exhaust pipe grime).

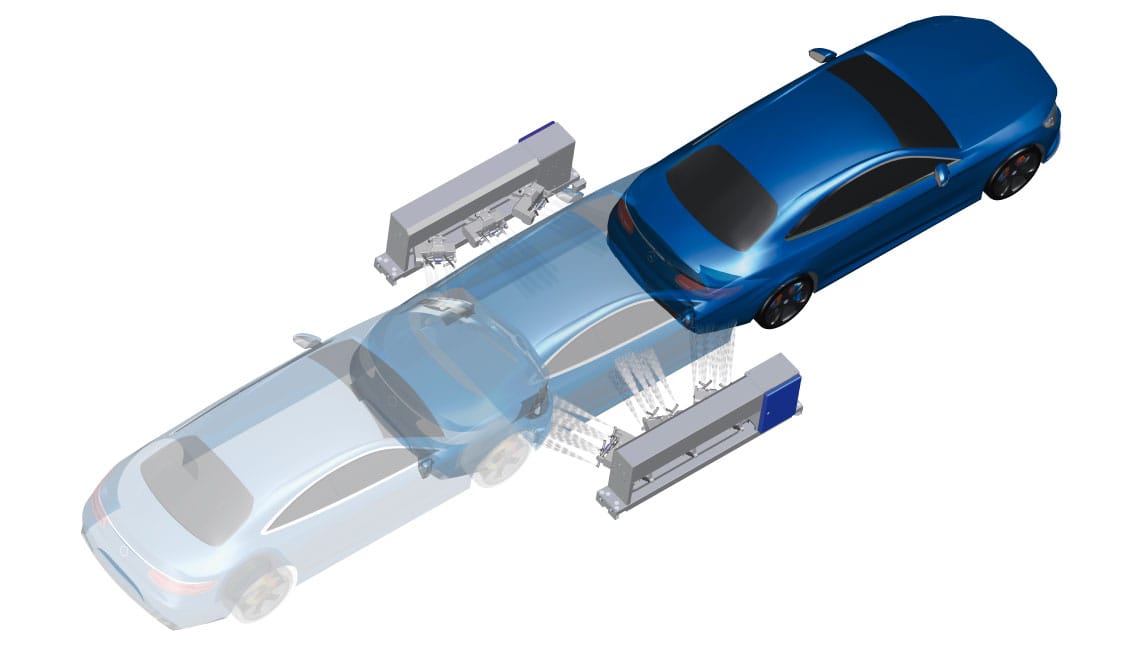

JETSTREAM-EXPRESS

An effective and powerful automatic high-pressure wash is strongly recommended for express wash concepts in order to prepare the vehicle for the subsequent brush wash. JETSTREAM-EXPRESS powerfully sprays the vehicle with its 5 oscillating high-pressure jet devices (Point spray jet). A working pressure of up to 50 bar at approx. 140 ltr/min can be achieved in combination with two piston membrane pumps suited for recycled water (up to 250 μm particle size). The jet devices spray against the vehicle at the start of the program and pivot in towards the vehicle’s end in the rear area for a thorough rear wash. The side devices work in alternating operation according to vehicle area. Frame material: Duraprotect

JETSTREAM SEMI-EXPRESS

Ideal for wash tunnels with semi-express wash concepts. The arch relieves the pre wash personnel and thus reduces the workload. The vehicle is cleaned by 4 oscillating high-pressure jet units (working pressure approx. 50 bar at approx. 70 ltr./min.) These spray parallel to the vehicle and turn towards the rear of the vehicle once reaching the vehicle’s end. Frame material: Duraprotect.

JETSTREAM-MATRIX Combination

The JETSTREAM-EXPRESS or the JETSTREAM SEMIEXPRESS can be mounted directly on the high-pressure wheel/sill washer MATRIX. This way, a compact highpressure pre-wash combination is created. We are flexible: Upon request, we can also combine piston membrane pumps with 80 bar and adjust the amount of high-pressure jet devices according to the specific project.

Middle-pressure spray device, mounted on Evolution Wash Portal

For full-surface rinsing of softened dirt by middlepressure spray jets. The spray pipe can be mounted to various Evolution Wash Portals (in the picture on the frame of the kinematic roof cylinder). Designed for supply by centrifugal pump up to 16 bar at 100 ltr./min.

Middle-pressure spray device, DURAPROTECT arch.

High-grade middle-pressure arch in DURAPROTECT frame material. The piping with the spray jets is mounted on the rear of the arch. The arch is designed for supply by a centrifugal pump up to 16 bar at 100 ltr./min. (upon request also combineable with piston membrane pumps).

Middle-pressure spray device, aluminum profile arch

Cost-efficient middle-pressure arch designed with powder coated aluminium frame profile. The piping with the spray jets is mounted on the rear side of the arch on mounting consoles. The arch is designed for supply by a centrifugal pump up to 16 bar at 100 ltr./min.100 l/min.

Wheel / sill wash device TIREJET

The TIREJET cleans the sill and wheel areas, with an electrically driven, 360° rotating high-pressure jet device. It is ideally situated following a brush wheel wash unit in order to rinse off softened rim dirt. Working pressure: up to 50 bar at approx. 70 ltr./min. (supply via piston membrane pump capable of functioning with recycled water).

Wheel-/ Sill wash device HD-ROTATION, accompanying

Effective high-pressure cleaning for sill and rim areas. HP-ROTATION is especially designed for installation and application following the wheel brush wash unit. Two oscillating high-pressure devices wash dirt off of each side (0° jets) of the vehicle in an accompanying movement (1.000 mm). A working pressure of up to 80 bar at approx. 70 ltr./min. can be achieved in combination with a piston membrane pump suited for use with recycled water (up to 250μm particle size).

Optional: Pivoting device

Pivoting device for 3 adjusted angles: Slanted against vehicle front corners, then parallel to the vehicle, then slanted against vehicle rear corners.

Wheel / sill wash device HP-MATRIX, accompanying

For high-pressure cleaning of sill and rim areas and especially wheel arches. This aggregate is the ideal complement for wash tunnels with an express wash concept. Large dirt particles are thoroughly removed and the vehicle is ideally prepared for the following wash stations. Two oscillating high-pressure devices wash dirt off of each side (0° jets) of the vehicle in an accompanying movement (1.000 mm).

The vehicle front and rear are washed by a pneumatic pivoting movement. A working pressure of approx. 50 bar at approx. 69 ltr./min can be achieved incombination with two recycled water suitable piston membrane pumps (up to 250 μm particle size).

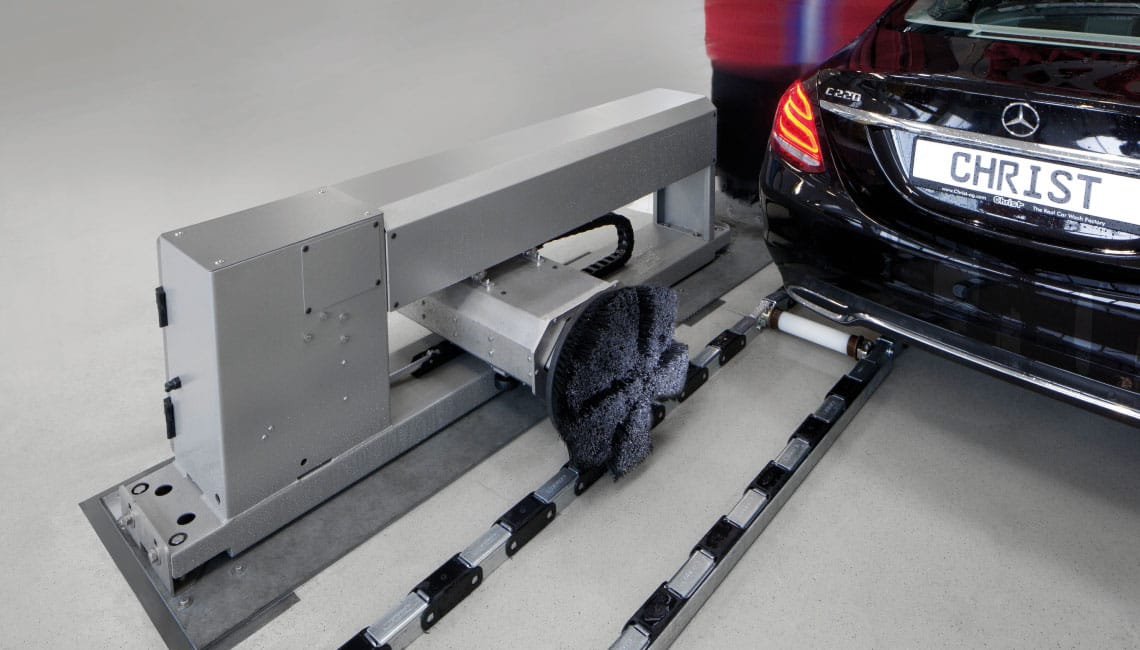

Wheel / sill wash device, longitudinal

For intensive cleaning of the wheels and the lower vehicle side parties by horizontal wash cylinders on the left and right sides. Both horizontal wash cylinders pivot in the driving direction, mounted in a tand construction and adjust to the exact width of each vehicle.

The wheel wash principal remains the same: The wheel area is washed by the wheel turning while passing the wash cylinder (left wheels turn on double chain conveyor along the cylinder).

Optionally available: Wash material BRUSH PREMIUM

Special polyethylene brushes (black/grey) with profiled trimming and mixed brush hair model (brush hair geometry, diameter and length) for increased cleaning performance.

Wheel wash device, wheel accompanying

Both wheel wash brushes are synchronously and pneumatically guided on the wheel pair to be washed. Correct control of the applied brush pressure as well as correct inner irrigation of the brush guarantees a thorough rim wash. The wheel washer is activated via a light barrier system. Starting at this point it runs frequency controlled 1.000 mm with the wheels.

Wheel wash device

Stable linear guidance of the inner, irrigated wheel wash brushes. High cleaning performance through pulsating brush grip and rotation direction change. Wheel recognization via light barrier.

Medium-pressure spray device for front, under-body and rear, floor installation above-ground

Designed for touchless cleaning of the lower front and rear surfaces with medium-pressure. The water jets overlap underneath the vehicle in the wash program “under-chassis wash”. This aggregate is capable of being retrofitted in wash tunnels with existing foundations, due to its above-ground installation. With the respective supply device, the device can be operated with a working pressure of approx. 15 bar at approx. 100 ltr./min..